I WORRY that we face a crisis deeper and more complex than any of us have seen before because of the confluence of geopolitics, demographics, the changing nature of the Chinese economy as Common Prosperity reforms accelerate, China’s rising chemicals and polymers self-sufficiency, the high levels of global inflation with all its causes, and, last but certainly not least, climate change.

I began a series of posts on each of these themes last month with a focus on China. But before I move onto to other posts in this series, addressing each of the other themes in detail along with suggested solutions, see below Executive Briefing.

As always, let me stress that these are my personal views and do not represent the views of ICIS.

The China challenges

China has shifted away from “growth for growth’s sake” as it pushes for greater wealth equality, lower debt and cleaning up the environment. This means lower chemicals demand growth than is commonly expected over the long term.

We don’t know if China will make a success of its new economic growth model. The model may not work because of geopolitics and demographics – its rapidly ageing population. Returning to the old model would, I believe, be very difficult.

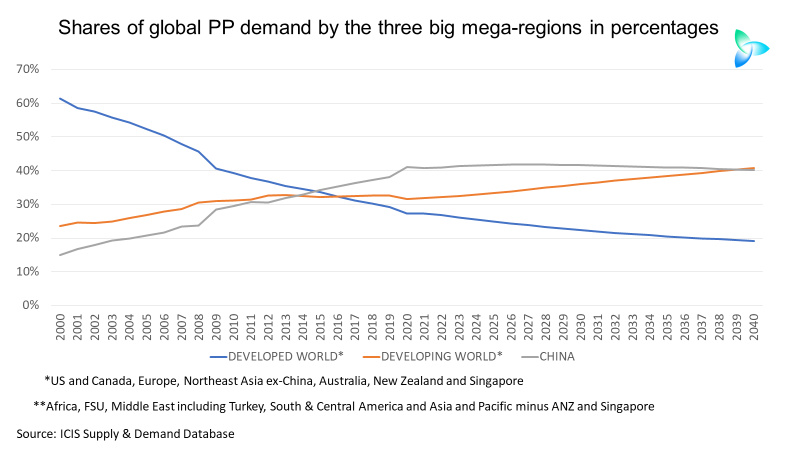

To illustrate the scale of our dependence on China, see below the ICIS estimate of percentage shares of global polypropylene (PP) demand divided into three mega-regions from 2000 until 2040. It is the same in all the other chemicals and polymers.

It is not until 2040 when we expect the developing world’s share of global demand (the population is forecast to be 6.5bn by then) to edge ahead of China’s share (ICIS estimates its population at 1.4bn in 2040).

Note how China overtook the developed world in 2016 and how the gap has widened ever since. On a per capita basis, China overtook the US in 2019 despite China being a much poorer country than the US.

China’s outperformance relative to its wealth partly reflects its dominance of global manufacturing (some 10-15% of Chinese PP demand is accounted for by exports of finished goods).

This dominance in manufacturing is under threat from geopolitical and demographic challenges that are discussed below.

Meanwhile, local-for-local demand growth for PP and all the other petrochemicals may, as I said, be lower than expected because of the Common Prosperity economic reforms.

The next chart shows the three mega-regions with their percentage shares of global PP demand relative to their shares of the global population – again from 2000 until 2040.

If China can no longer outperform to the same extent, will the other regions be able to pick up the slack, given that they too are likely to face challenges similar to those confronting China?

In the short -to medium-term, China’s zero-COVID polices will add further downward momentum to the economy. The zero-COVID policies appear likely to continue for health and political reasons.

China is also moving much closer to petrochemicals self-sufficiency than was widely expected, first through building lots more conventional plants and then, perhaps, through big growth in mechanical and chemicals recycling.

Geopolitics, sustainability and the breaking up of global supply chains

The benign period of geopolitics following the collapse of the Berlin Wall is over, most notably because of the split between the US and China and Russia’s invasion of Ukraine.

Geopolitics appear likely to continue to disrupt trade flows of raw materials such as chemicals, oil, gas and fertilisers.

This new era of geopolitical volatility will lead to global supply chains being localised to fit national political agendas – for example, the $52bn Biden semiconductor bill that will localise innovation and production in the US. This will reduce US dependence on semiconductor imports.

As supply chains in general become more localised and regionalised (we could end up with two economic and geopolitical zones, one dominated by the US and the other by China), the old outsourcing model may unravel.

Chemicals may no longer flow as freely across borders as complete production chains are nationalised or regionalised.

The chart below, again using PP as an example, shows how demand could split between US-led and China-led zones under two different scenarios, assuming our base estimate for global PP demand in 2022-2040 is correct.

Supporting the shift away from global to regional and national supply chains could be global carbon and plastic waste taxes or credits (see below).

Inflation, recession, austerity and demographics

We face a global recession because of inflation. Central bank-driven debt built up since the Global Financial Crisis risks turning a recession turning into a depression. Today’s conditions are anomalous to the 1970s when US interest rates peaked at nearly 20%.

Austerity could support the sustainability agenda. Because people will have less money to spend, this may encourage a return to “build to last”, i.e. smartphones including batteries designed to last more than two years, and the decline of environmentally damaging industries such as fast fashion.

Economic growth, and so petrochemicals demand, in the developing world may not expand by as much as is commonly expected because of climate change. See this important January 2020 McKinsey study.

Very youthful populations in the developing world (Africa, the Middle East including Turkey, South & Central America, Asia and the Pacific minus its developed economies and the Former Soviet Union) mean that governments need rapid growth to maintain social stability.

But climate change and declining demand for hydrocarbons on the rise of electric vehicles threaten to slow growth. Major social and political unrest could happen unless new growth models can be built on greening economies.

Rapidly ageing populations in China (one of the reasons for its economic reforms) and the West threaten much lower growth unless new more sustainable growth models – in terms of both debt and the environment – can be built.

Sticking with PP as an example, what might a global downside to demand look like in 2022-2040? See the chart below.

You may argue that even our base cases for the three mega-regions involve sharply reduced annual average growth forecasts from actual growth in 2000-2021. Why, therefore, assume even lower growth outcome?

Because of the severity of the challenges outlined above. Some would say that my downsides are too conservative and that, instead, we will see “dematerialisation” – growth shrinking. This risk is said to apply, in particular, to the developed economies.

A global cost on carbon and plastic waste

Chemicals and other commodity price forecasts may eventually need to include a global price on the cost of carbon that will change cost-curve economics. This is on the assumption that a global cost is levied on carbon, probably through a combination of taxes and credits that would be traded.

The most efficient producers are likely to be those who best manage carbon through lower-emissions production technologies and through carbon capture and storage.

A global price on plastic waste, following the March 2022 Nairobi agreement by 175 countries to work towards an agreement on reducing plastic waste in the oceans in the next two years, could happen.

Polymer producers may face plastic taxes and credits. This would, hopefully, fund adequate rubbish collection systems in the developing world.

I see lack of these collection system as the root of the crisis. Some 3bn people, predominantly in the developing world, lack access to good-enough collection systems.

Around 2bn people have no collection systems at all, meaning that they have no choice but to dispose of plastic waste in the open environment.

Lower growth and extra costs of environmental compliance may reduce the return on capital employed by the global chemicals industry. Companies could be run more as utilities.

The “less is more” petrochemicals growth models

If the scenario I presented above is realised, what follows is how our industry would, I believe, need to transform itself. Many companies are already well down this path. The ones who fail to head in this direction will be in a lot of trouble.

The chemicals industry can, and must, play a very active role in the transition to new growth models that mitigate many of the problems outlined above.

Companies can, of course, do nothing about geopolitics. But they must become more active and responsible stewards of the environment, and, in the process unlock great financial return. Here’s how:

- Innovation must accelerate in developing low or zero-carbon chemicals production processes.

- Companies must help fund collection, sorting, storage and recycling systems in the developing world.

- Companies must work more closely with converters, brand owners and retailers to reduce the need for virgin plastics in single-use applications.

- New chemicals and polymer solutions are required to make finished goods last longer. The solutions must again be developed through close collaboration with converters, brand owners and retailers.

- Companies must shift from volume to service models. Instead of success being judged on how many extra tonnes they keep selling, success needs to be measured on the effectiveness of service-based supply models.

- For instance, a synthetic rubber producer works with a tyre manufacturer to secure a 30-year contract with a car hire company. Fees are based on commonly agreed and shared environmental targets to reduce consumption of new tyres through data analysis of driver behaviour – e.g. the severity of breaking and rates of acceleration over short distances. Car hire customers are incentivised to drive more smoothly. The synthetic rubber producer and tyre manufacturer are incentivised to make their products last longer.

- The shift to service-base models will enable companies to hit ever-more stringent emissions targets – and will allow them to capture market share as public and legislative pressure to make things last longer increases.

- Legislators need to get rid of quarterly financial reports to make a service-based model work. This will allow companies to build long-term business plans that may take years to be profitable.

I firmly this is the direction in which the chemicals business must travel over the next ten years. Contact me at john.richardson@icis.com for details on how ICIS can help you with this transition.